Time waits for none. Apparently, it's the same case with the speed of Technology upgrade these days. Moore's law is already broken. The happening innovation keeps us wondering 'how amazing it is' and 'what's next' at the same time. Since always, Advancements in technology are inspired by Science Fiction and action movies for implementing the fictional gadgets into reality. On 26th October 2017, a gynoid ‘Sophia’ with state of the art artificial intelligence was given citizenship of Saudi Arabia. Who would have thought of this event would be possible when we saw C-3PO in ‘Star Wars’ movie Franchise as one of the first and most memorable humanoid robot characters ever seen in the movies.

What is a Humanoid Robot?

Humanoids are the robots which are designed as to look like humans. Why Humans? Well, robots are created by humans to reduce the repetitive manual work which was previously done by them. So why not design it like humans. Let us not forget, humans have evolved over time and again since millions of years in the first place. This human type design provides better grip for regular tasks, better awareness of obstacles and better interaction with humans. Most importantly, it is proved immensely helpful for biological advancements in the human body. You can find all kinds of robotic applications available from DIY to Integrated with our nervous system. The more it amazes you, the costlier it gets. If you go for most advanced, just a limb can cost you a hundred thousand dollars.

In the initial years, it was only thought for automating repetitive manual in the industrial sector. It was implemented and working fine for a long time now. After the advancements in biological engineering, hopes in the consumer sector gained momentum. Today, after the introduction of artificial intelligence (AI), the scenario has taken a drastic upside turn for the scope and advancements in this field. After the integration of AI, it is practically a Human being. It doesn’t only look like a Human being but it has its own thought process, own strategic thinking ability and although they may not be able to feel, but it can acknowledge the possible emotion as well.

Unmanned robots have already found their way into applications in our day to day lives. Recently, it made its debut as an Olympic Torchbearer in South Korea. Although most of these robots contribute to Floor Cleaning Robots, they have acquired their place in every segment of tedious work done by humans. Now, as humans can be a major threat to mankind, Debates have come up with a swirl on whether AI can be a threat to mankind as well. These two have amalgamated so well that there’s nothing wrong in saying that now the words ‘Humanoid Robots’ and ‘Artificial Intelligence’ go hand in hand.

Today, we have a wide range of Robots available in the market from ₹4000 to whatever you can pour in. However, the best one will be the one created by you yourself. It covers best of both worlds, Electronics and Computer engineering and gives you a product which is a peerless example of how innovation happens at the edge of two different domains. Let’s see how basics are used to create one of the leading advancements in the world today.

Robots like Humans:

We will first understand that how the mechanics of our body and robots can be very similar to a very common and easy DIY Experiment.

DIY Basic hand:

You need 4 straws, Cardboard Plank, Glue, Scissors and 10m Thread reel

Cut the card in the shape of a Hand i.e. Arm extension into four fingers. (Let us ignore thumb for now). Fold all four finger extensions on cardboard such that it forms two joints and three phalanges on each finger. Now cut the straw and glue them on each phalanx. Make sure their size is smaller than their respective phalanx. Now cut the thread into four parts and pass it through each of these fingers. One end of the thread should be fixed at the open end of the finger while the other end of the all four pieces should be tied together. Your basic hand is ready. Now, when you hold the cardboard hand from the position of the wrist and pull the Knot where it is tied together, you can see the four fingers bend in the motion just like our hand when we grip something. You can see for yourself how individual fingers by pulling individual threads instead of the knot as well. You have created one of the most basic robotic arm architecture.

What did we learn from this architecture? Notice how each finger has its own thread to get pulled, see a single pull gives motion to each phalanx one by one and when we need to use multiple fingers, just pull all together and note that each work together. Their action might be delayed and each finger may form curve at different speeds as we are pulling different length of the fingers with the same force, from the same point.

These are some of the small things which are taken into the consideration while making each part of the limbs and also the torso. This is proved helpful for the people with disabilities, without an actual limb. The nerve used for moving any of the fingers must be passing from the upper hand. For someone whose arm is only till the ankle, sensory cords are connected to the lower part of the upper arm and an electronic armature is created to move with respect to the motion of the muscle at that lower part of the arm. This way, one can have an arm controlled by our brains just like any other arm.

These aren’t exactly the types of machines used these days. Today, we have Robotic to Human size ratio of 1:1. The latest arms are equipped with synchronous motors which are used for simultaneous movements with single instruction. But for machineries and repetitive manual work, most widely used structure is Six-axis Powerball arm. They are made of 3 Ball joints, 5 joints overall; one ball joint can be considered as a shoulder joint, another ball joint will replace the ankle while the last ball joint forms the wrist. The rest of the structure can be considered as upper and lower arm structure which provides strength to the arm structure. It is created in such a way that it can cover all the area in its outreach, unlike our hand. For example, you cannot bend your hand in the backward direction from the ankle but this structure can do turn in every direction; the only limit is its length.

Legs in a Humanoid Robot:

The joints are same as hand but instead of hand architecture, we can use hoverboard kind of architecture as it would be the most convenient one for its movement from one place to another. Although it’s lower body as well as upper body, especially the limbs are created as per the requirements and the purpose for what it’s made and hence, Hoverboard architecture is rarely used for the lower limbs. They are been made to be same as humans internally as well as externally. The artificial Rib cage is used for its Torso part which gives protection to the internal circuit and mechanics. Legs are created to duplicate the maneuver just like human legs.

Other Devices in Humanoids:

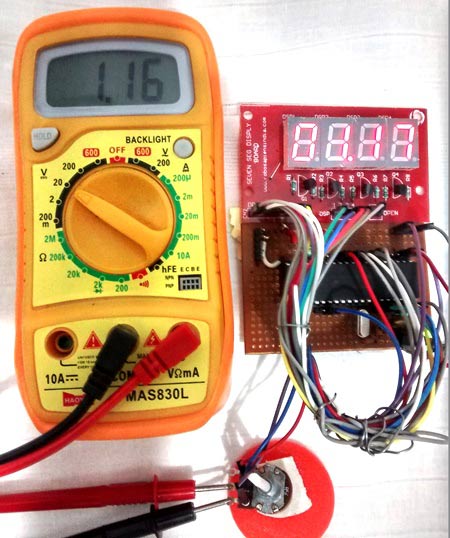

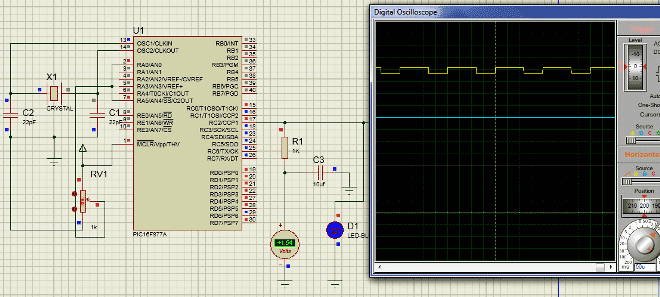

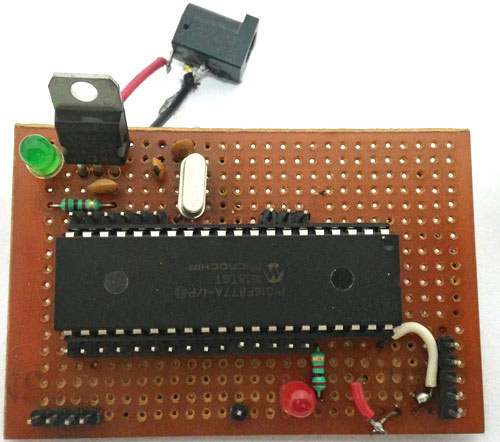

Other minimal device requirements for creating a Humanoid are HD Cameras, which will help collect data for Image processing, RFID, which will help give us instructions remotely, IR Sensors, to detect obstacle, humans, and distance from them, Rotors, for their movement, Accelerometer, Magnetometer, Gyroscope and Ethernet connection for controlling the movement if needed, A CPU, A Battery Unit, A PLC is must for regulated outputs and designing the logic.

Main Applications of Humanoids:

There are unlimited possibilities with robots and humanoids from doing a repeated manual task, to think and take a decision using Artificial Intelligence. Here I am mentioning few main areas where Humanoids are used:

Personal Home Assistants:

Integrating IoT with these robots will create a personal Home assistant which manages your Electricity, Light, Sound, and Temperature at your home using your home automation system.

Virtual Reality:

Integrating Virtual Reality with these robots and programming them to replicate our motion movements will give you a replica of yourself which will be useful in Fire, Flood, Experimentation or other dangerous situation where human life can be at stake. We can find all kinds of application of this futuristic bots but let’s discuss the most important one. The one which will be the most helpful for the people in need: Prosthetics.

Prosthetics:

Prosthetics is one of the main reasons why it is made to look like actual body parts. Humanoids can be used a transplant or a replacement of a body part which will be connected to the nervous system of the body. A person without hand after elbow can make the hand customized for oneself to be connected to the nerves below the upper arm near the shoulder. Each nerve movement and extension of the inner part of the upper arm will give a unique signal to the brain. This signal will be corresponding to a specific hand movement; the modular prosthetic limb will recognize the muscle pattern and movement in the hand will take place accordingly. Not to forget that each of these things will happen in real time. Just by the trigger of a thought, you can move the hand just like it is your own hand. It will change the way special people live. It will be helpful for the people who went through an accident and lost a limb or other body part. The best technology available today also has over 100 sensors in the palm itself, providing sensation capabilities of an actual touch on the surface of the artificial arms and legs which provides successful targeted sensory innervation and feel.

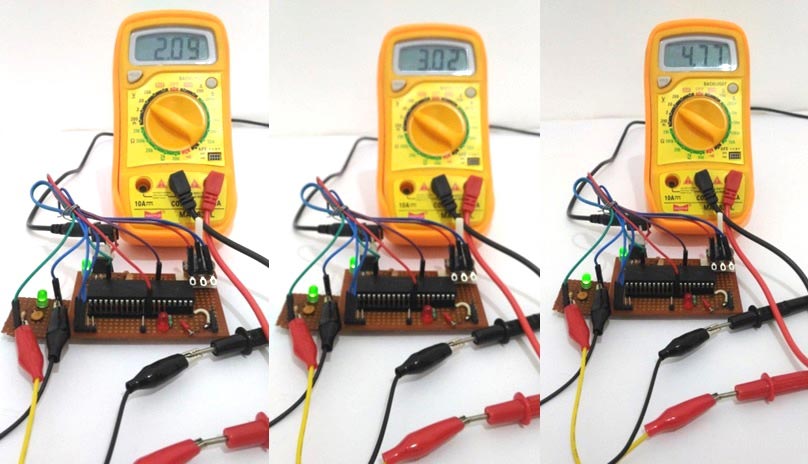

Mind Controlled Prosthetic Arm developed by DEKA Research & Development Corp

Mind Controlled Prosthetic Arm developed by DEKA Research & Development Corp

The creation and advancements of this Humanoid Robots are never-ending. Major innovations and breakthroughs happen every day in this very field. Numerous applications from industrial to now in our day to day life direct the trend of these droids to keep up and turn upwards. Multiple jobs will be replaced by robots in near future. This issue is debated in the parliaments around the world. The idea of ‘Basic income for everyone’ was introduced as one of the options while keeping the recessions and unemployment in mind. The government of several countries has shown resistance and placed their thoughts about putting a ban on AI while some of the governments showed interest in restriction of the applications of humanoid robots and them replacing the jobs.

The importance of these products can be easily seen with the surge of the issues, merits, and demerits being discussed in the houses. One thing is for sure, with the mixture of best in the class software of Artificial Intelligence and these best in class physical structures of circuitry, the product which is known is going to take over the world very fast even with any restrictions. And the development of these kinds of Humanoids has already started, as we can see the Sophia Robot as the great example of Artificial Intelligence with perfect human physical structure.